Training Your Staff on Basic PAT Inspections

Electrical safety is one of the most important aspects of workplace health and safety. Faulty or damaged electrical appliances are among the leading causes of accidents, fires, and downtime in businesses. This is where Portable Appliance Testing (PAT) comes in. PAT ensures that all electrical appliances are safe to use, preventing hazards before they escalate.

While professional PAT testing by qualified electricians is essential, you don’t have to wait for the annual or periodic inspection to ensure safety. Training your staff on basic PAT inspections—mainly visual checks—empowers them to spot early signs of danger, handle equipment more responsibly, and build a culture of safety within your organization. To Know More Click Here

Why Train Your Staff in PAT Inspections?

- Early Hazard Detection

Many faults can be spotted visually before they pose serious risks. For example, frayed wires or loose plugs are clear red flags that employees can identify and report immediately. - Cost Savings

Catching problems early reduces costly repairs and downtime. It also helps businesses avoid potential penalties for non-compliance with safety regulations. - Regulatory Compliance

Health and Safety Executive (HSE) guidelines emphasize regular checks on electrical appliances. While not every staff member can be a certified tester, training them in basic inspection techniques ensures compliance support. - Promotes Safety Awareness

When staff are trained, they become more conscious about how they use, store, and maintain equipment. This reduces careless mistakes like overloading sockets or mishandling appliances. - Supports Professional PAT Testing

Training staff doesn’t replace professional inspections but complements them. Employees act as the first line of defense, while certified electricians handle the more detailed testing.

What Your Staff Can Be Trained to Check

Most basic PAT inspections revolve around simple, non-technical visual checks. With minimal training, your staff can be guided to spot:

- Damaged Power Cords – Cracks, cuts, or fraying on wires that could expose live conductors.

- Loose or Cracked Plugs – Signs of wear and tear, loose screws, or broken casing.

- Burn Marks or Overheating – Discoloration on plugs or sockets, which may indicate overheating or internal faults.

- Correct Use of Appliances – Ensuring staff don’t use equipment for unintended purposes (e.g., plugging a high-wattage device into a low-rated extension).

- PAT Labels and Expiry Dates – Checking whether an appliance has a valid PAT sticker and ensuring it hasn’t expired.

- Trip Hazards – Ensuring cables are safely managed to avoid slips and falls.

Tip: Provide your staff with an easy-to-use visual inspection checklist. This will help standardize inspections and make reporting issues much easier. To Know More Click Here

How to Train Your Staff Effectively

Training your team doesn’t have to be complicated. A well-structured program should include:

1. Awareness Sessions

Start with why PAT testing matters. Use real-world examples of electrical accidents to highlight the importance of early detection and safety.

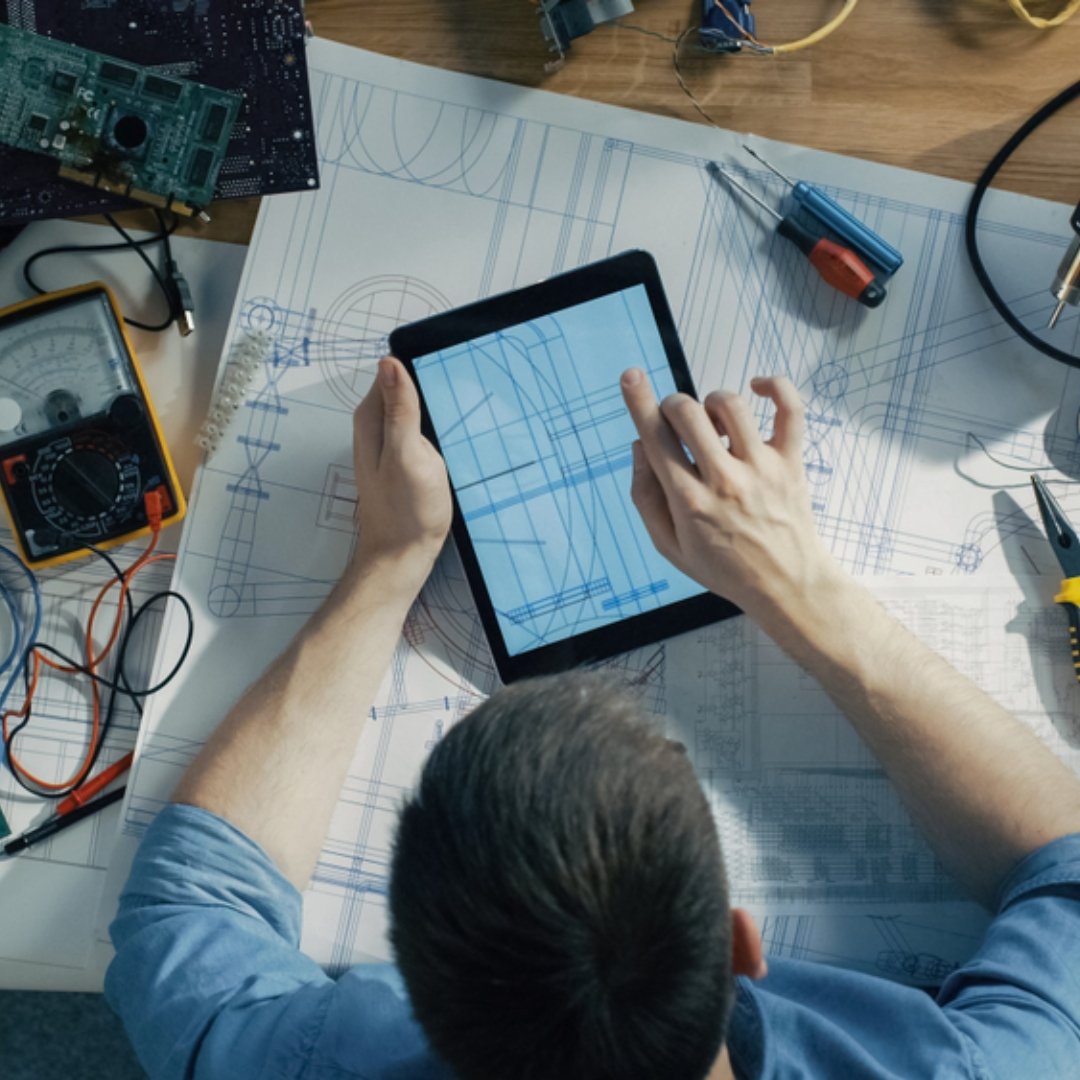

2. Hands-On Demonstrations

Show staff examples of both safe and unsafe appliances. Use damaged plugs, burned sockets, or frayed wires as case studies. Practical training leaves a stronger impact than theory alone.

3. Simple Checklists

Create a step-by-step checklist for visual inspections. For example:

- Is the plug intact?

- Is the cable free from cuts or twists?

- Is there any smell of burning or visible overheating?

- Is the PAT label valid?

4. Reporting Procedures

Make it easy for staff to report unsafe equipment. Assign a supervisor or safety officer who collects reports and ensures that faulty equipment is taken out of service immediately.

5. Refresher Training

Electrical safety isn’t a one-time lesson. Conduct refresher courses every 6–12 months and update checklists if regulations or workplace conditions change. To Know More Click Here

The Role of Professionals in PAT Testing

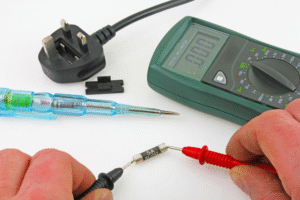

It’s important to stress that staff training does not replace certified PAT testing. Professional electricians use specialized equipment to test electrical continuity, insulation resistance, earth bonding, and more—things staff cannot do with just a visual inspection.

Instead, staff training should complement professional testing. Employees act as the first defense against hazards, while certified professionals provide the technical validation that ensures compliance and long-term safety.

Practical Benefits for Businesses

Businesses that invest in staff PAT training often see:

- Fewer workplace accidents and injuries.

- Reduced equipment downtime due to early detection of faults.

- Lower insurance risks and costs.

- A reputation for prioritizing employee safety.

- Improved compliance with health and safety regulations.

Conclusion

Training your staff on basic PAT inspections is an investment in safety, efficiency, and compliance. While professionals are essential for detailed PAT testing, empowering employees to carry out simple visual checks makes your workplace safer and more proactive.

By combining staff awareness with professional expertise, you create a strong safety net that protects your people, your equipment, and your business operations.

SafeTag – Your Safety Partner in New Zealand

Ensure workplace safety and compliance with SafeTag’s professional testing services. We offer certified solutions for Electrical Testing & Tagging, RCD Testing, Microwave Leakage Testing, and Portable Appliance Testing (PAT). Trust our experts for hassle-free, on-site service tailored to your business needs.