Understanding Visual Inspection vs. Electrical Testing

Electrical safety is one of those things we rarely think about until something goes wrong. But the truth is, most electrical hazards build up quietly over time—through wear, unnoticed damage, or hidden faults. To prevent accidents, two major methods are used across industries and households: visual inspection and electrical testing. At first glance, they may sound similar, but they serve different purposes and offer unique benefits. Let’s explore how they work, why they matter, and how they complement each other. To Know More Click Here

What is Visual Inspection?

Visual inspection is the simplest yet most effective first step in checking electrical safety. It involves a close look at equipment, appliances, and wiring systems to spot visible defects or warning signs. Some examples include:

- Frayed or damaged cables

- Burn marks, discoloration, or signs of overheating

- Loose connections or broken plugs

- Missing covers or exposed wires

- Water damage or corrosion around electrical outlets

Because it requires no specialized tools, visual inspection can be carried out more frequently by anyone with basic awareness. For workplaces, trained staff can conduct routine inspections as part of daily or weekly safety checks. In households, just noticing and acting on something that looks “off” can prevent serious hazards.

Key point: Visual inspection is about catching the obvious and preventing small problems from becoming big risks. To Know More Click Here

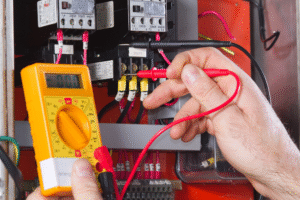

What is Electrical Testing?

Electrical testing takes safety a level deeper. Unlike visual inspection, it cannot be done with the naked eye. Instead, it relies on specialized testing instruments handled by trained professionals. These tests measure electrical performance and check whether safety standards are being met. Common tests include:

- Earth continuity test: Ensures a safe path for fault current.

- Insulation resistance test: Confirms insulation is strong enough to prevent shocks.

- Polarity test: Verifies wiring connections are correct.

- Leakage current test: Detects dangerous current leakage from appliances.

Electrical testing reveals hidden dangers like internal wiring faults, overheating inside equipment, poor grounding, or deteriorating insulation—things no visual inspection could catch. In many workplaces, this process is formally known as Portable Appliance Testing (PAT) or similar depending on local regulations.

Key point: Electrical testing provides data-driven evidence of safety and compliance.

Key Differences Between the Two

- Purpose – Visual inspection identifies visible faults (frayed wires, burn marks), while electrical testing uncovers hidden internal issues.

- Tools Needed – Visual inspection requires no tools, electrical testing relies on specialized meters and instruments.

- Skill Level – Visual inspection can be done by anyone with awareness, whereas electrical testing requires trained professionals.

- Frequency – Visual checks can be carried out frequently (daily or weekly), while electrical testing is done at scheduled intervals.

- Limitations – Visual inspection cannot detect hidden faults, and electrical testing may miss obvious surface damage if inspection is skipped. To Know More Click Here

Why Both Matter

Visual inspection and electrical testing are not substitutes; they are partners in safety. Think of them like two halves of a shield.

- Visual inspection keeps you alert to problems you can see immediately—like a burnt socket.

- Electrical testing dives into the unseen, ensuring the wiring and circuits are functioning correctly.

For complete safety, both should be part of a routine maintenance plan. For example, in offices or factories, regular visual checks can be done by staff, while annual or bi-annual electrical testing is performed by professionals. In homes, simple vigilance (spotting damaged plugs or overheating) combined with professional testing ensures long-term protection.

Benefits of Combining Both

- Comprehensive Safety – Covers both visible and hidden risks.

- Regulatory Compliance – Many industries legally require testing and inspections.

- Cost Savings – Early detection reduces repair costs and prevents accidents.

- Peace of Mind – Knowing your systems are both visibly and technically sound ensures confidence. To Know More Click Here

Conclusion

Understanding the difference between visual inspection and electrical testing helps you create a layered defense against electrical hazards. Visual inspection provides quick, frequent checks for obvious problems, while electrical testing delivers detailed, technical assurance of safety. On their own, each method has limits, but together they form a reliable system of protection.

Whether you’re running a household or managing a workplace, combining these two practices reduces risks, prevents downtime, and safeguards both people and property.

SafeTag – Your Safety Partner in New Zealand

Ensure workplace safety and compliance with SafeTag’s professional testing services. We offer certified solutions for Electrical Testing & Tagging, RCD Testing, Microwave Leakage Testing, and Portable Appliance Testing (PAT). Trust our experts for hassle-free, on-site service tailored to your business needs.