The SafeTag Process: What to Expect During an Electrical Inspection

When it comes to workplace safety and compliance, electrical inspections are non-negotiable. Faulty wiring, overloaded circuits, and unsafe appliances can pose serious risks, from fire hazards to employee injuries. That’s where SafeTag steps in—with a reliable, step-by-step electrical inspection process designed to keep your business safe, compliant, and worry-free.

But what exactly happens during a SafeTag electrical inspection? Let’s walk you through it. To Know More Click Here

1. Initial Consultation and Site Assessment

Every SafeTag inspection starts with a clear understanding of your premises and requirements. Our team communicates with your facility managers to:

- Identify the type of site (office, warehouse, industrial, etc.)

- Determine the number and type of appliances or systems

- Schedule the inspection with minimal disruption to your daily operations

This planning stage ensures our team arrives prepared with the right tools and understanding of your workplace layout.

2. Visual Inspection of Electrical Systems

Our trained technicians begin with a comprehensive visual inspection. This involves:

- Checking the condition of plugs, sockets, switches, and wiring

- Identifying signs of overheating, corrosion, or damage

- Ensuring electrical load is appropriate for connected appliances

- Spotting any unsafe DIY repairs or outdated components

This step helps uncover obvious defects that could become safety threats if left unaddressed. To Know More Click Here

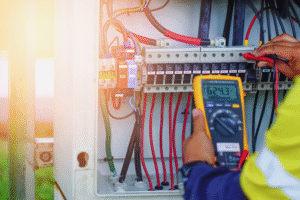

3. Testing and Measurement with Certified Equipment

After the visual check, SafeTag proceeds with technical testing using calibrated instruments. This includes:

- Earth continuity testing – verifies the proper grounding of appliances and outlets

- Insulation resistance – checks for electrical leakage and potential short circuits

- RCD (Residual Current Device) testing – ensures safety switches trip correctly

- Voltage and load checks – confirms that systems operate within safe limits

Each result is carefully recorded and categorized based on urgency and compliance standards.

4. Compliance Checks Against Regulatory Standards

Our inspection process follows all relevant legislation and safety frameworks, including:

- The Electricity at Work Regulations 1989

- AS/NZS 3760 standards for electrical testing and tagging

- Workplace Health and Safety Guidelines specific to New Zealand regulations

Any non-compliance is flagged with clear recommendations for repair or replacement. To Know More Click Here

5. Clear Labelling and Documentation

Once the inspection is complete, SafeTag provides:

- Pass/Fail labels for appliances and equipment

- Detailed digital reports outlining test results, risks identified, and suggested actions

- Compliance certificates for workplace audit and insurance purposes

We ensure all documentation is organized and archived for future reference—helping your business stay ready for inspections or claims.

6. Follow-Up Support and Maintenance Recommendations

At SafeTag, our job doesn’t end with the inspection. We offer:

- Regular maintenance schedules and reminders

- On-call advice for electrical safety queries

- Help coordinating follow-up repairs if needed

Our goal is to build a long-term safety culture within your organisation. To Know More Click Here

Why Choose SafeTag for Your Electrical Inspections?

- Certified and trained inspectors

- Minimal disruption to daily operations

- Full transparency with digital reports

- Cost-effective safety and compliance

We don’t just inspect—we partner with you to keep your workplace powered and protected.

Conclusion: Know What to Expect and Stay Compliant

Electrical inspections shouldn’t be a mystery. With SafeTag, the process is clear, professional, and rooted in safety best practices. Whether you manage a small office or a large industrial site, our inspection process ensures every corner of your electrical infrastructure is reviewed, tested, and compliant.

Book your next electrical inspection with SafeTag today—and ensure safety without the stress.

SafeTag – Your Safety Partner in New Zealand

Ensure workplace safety and compliance with SafeTag’s professional testing services. We offer certified solutions for Electrical Testing & Tagging, RCD Testing, Microwave Leakage Testing, and Portable Appliance Testing (PAT). Trust our experts for hassle-free, on-site service tailored to your business needs.