Best Practices for Electrical Testing & Tagging

Electrical Testing and Tagging (also known as Portable Appliance Testing or PAT) is a critical component of workplace safety. It ensures that all electrical equipment is in good working order, compliant with safety regulations, and safe to use. Faulty electrical equipment can cause shocks, fires, or damage to property, making regular testing and tagging essential for businesses, offices, construction sites, and industrial environments.

Following best practices not only protects employees and equipment but also demonstrates compliance with safety standards and reduces liability risks. Below, we outline the key best practices for effective electrical testing and tagging. To Know More Click Here

1. Schedule Regular Testing

Creating a regular testing schedule is vital for maintaining workplace safety. The frequency of testing depends on the type of equipment and the environment in which it is used.

- High-risk environments such as construction sites, manufacturing floors, or outdoor areas require more frequent testing, often every 3–6 months.

- Low-risk environments like offices may only require annual testing.

- Maintaining a consistent schedule helps identify faults early and prevents unexpected breakdowns or hazards.

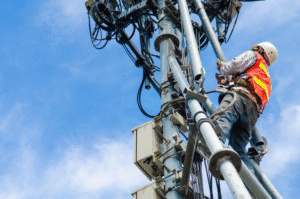

2. Use Qualified and Competent Technicians

Electrical testing should always be performed by licensed and trained professionals. Qualified technicians understand the complex standards and procedures involved in testing and tagging.

- They can detect hidden faults, such as internal wiring issues, insulation damage, or earth leakage.

- Unqualified personnel may miss dangerous defects, putting staff and property at risk.

- Choosing experienced technicians ensures compliance with national and industry-specific regulations.

3. Maintain Accurate Records

Keeping thorough records is essential for demonstrating compliance and tracking equipment history.

- Include details like the appliance name, serial number, test date, technician’s name, results, and the next inspection due date.

- Digital record-keeping can simplify tracking and reporting, especially for organizations with large numbers of devices.

- Regular audits of records help identify recurring problems and determine which equipment may need replacement. To Know More Click Here

4. Clearly Tag All Equipment

Tagging provides a visual indicator of safety and testing status for all users. Tags should include:

- Date of last test

- Next due test date

- Technician’s identification

- Pass/fail status

Proper tagging helps prevent accidental use of faulty equipment and provides assurance to staff and clients that safety protocols are followed. Use durable, legible tags resistant to water, dust, and abrasion, especially in harsh work environments.

5. Prioritize High-Risk Equipment

Certain types of equipment are more prone to wear and damage. These should be prioritized during testing:

- Portable tools like drills, grinders, and saws

- Extension cords, power boards, and adapters

- Equipment used outdoors or in wet, dusty, or industrial conditions

High-risk equipment should be inspected more frequently, and visual inspections between tests are strongly recommended.

6. Educate Staff on Safe Practices

Testing and tagging alone isn’t enough. Employees should be trained to:

- Visually inspect cords, plugs, and appliances for damage

- Avoid overloading power points or extension cords

- Report faulty equipment immediately

Fostering a safety-conscious workplace culture ensures that potential hazards are addressed proactively, even between formal testing cycles. To Know More Click Here

7. Remove Faulty Equipment Promptly

Any appliance that fails testing must be immediately removed from service.

- Clearly mark it as “Out of Order” or “Do Not Use.”

- Either repair or replace the faulty equipment before returning it to service.

- Prompt action prevents accidents and demonstrates the organization’s commitment to safety.

8. Stay Updated with Regulations

Electrical safety regulations evolve, and it is crucial for businesses to stay informed.

- Different industries may have specific requirements for testing intervals and documentation.

- Compliance ensures not only safety but also protection from legal and insurance issues.

- Regularly consult governing bodies or accredited safety organizations for the latest guidelines.

9. Conduct Pre-Use Visual Checks

Before even using electrical equipment, employees should perform simple visual inspections.

- Look for frayed cords, cracked plugs, or exposed wiring.

- Check for burn marks, unusual smells, or overheating.

- Visual checks complement formal testing and reduce the risk of accidents.

10. Implement a Safety Culture

Electrical safety works best when integrated into daily operations.

- Encourage reporting and accountability for electrical faults.

- Hold regular safety briefings to remind staff of testing schedules and protocols.

- Celebrate compliance and safety milestones to motivate ongoing participation.

Conclusion

Electrical Testing and Tagging is more than a compliance requirement—it’s a proactive step to ensure safety, efficiency, and peace of mind. By scheduling regular tests, using qualified technicians, maintaining accurate records, tagging equipment clearly, and educating staff, organizations can significantly reduce the risk of electrical hazards. Prioritizing high-risk equipment, removing faulty devices promptly, and staying updated with regulations further strengthens workplace safety.

Ultimately, the best practices in electrical testing and tagging create a safer, more responsible, and productive working environment for everyone.

SafeTag – Your Safety Partner in New Zealand

Ensure workplace safety and compliance with SafeTag’s professional testing services. We offer certified solutions for Electrical Testing & Tagging, RCD Testing, Microwave Leakage Testing, and Portable Appliance Testing (PAT). Trust our experts for hassle-free, on-site service tailored to your business needs.